Computer Vision in Manufacturing is rapidly becoming one of the most impactful technologies in modern production. As factories struggle with labor shortages, rising quality expectations, and the need to automate manual inspection, computer vision systems and artificial intelligence (AI) offer a scalable and cost-effective way to improve efficiency and reduce operational risks.

More and more leaders — including startup CEOs building their MVPs — are recognizing that adopting computer vision is not a futuristic idea, but a practical investment that pays off quickly. High-resolution cameras, intelligent sensors, and computer vision models can now analyze production processes in real time, detect defects with precision, and help companies maintain consistent quality standards even under demanding conditions.

What Is Computer Vision in Manufacturing?

At its core, computer vision is the process of converting images into actionable data. But in manufacturing, its value lies in what this data enables.

Traditional automation could only detect simple signals, such as motion or barcode scans. Modern computer vision systems, however, understand context and can answer questions critical for production performance:

- What exactly came off the conveyor belt?

- Is the item defective, damaged, or incomplete?

- Is the machine truly operating or just switched on?

- Are workers present at key stations to maintain workflow continuity?

By integrating computer vision into the factory floor, cameras become intelligent sensors capable of monitoring everything that happens at a workstation or production line. With high-resolution imaging, they can detect subtle variations that humans may overlook, especially during long hours of repetitive manual inspection.

This makes Computer Vision in Manufacturing one of the fastest-growing segments in industrial automation, giving factories real data, immediate alerts, and continuous visibility across processes.

Practical Use Cases: How Computer Vision Works on the Factory Floor

A key misconception is that integrating computer vision requires modern machinery or expensive technological upgrades. In reality, the highest ROI often appears in factories that:

- use older machines lacking digital interfaces,

- rely heavily on manual inspection,

- face challenges detecting defects early enough,

- want to automate conveyor belt monitoring or count produced items,

- aim to improve efficiency without disrupting existing production processes.

Below are examples of how computer vision systems are commonly used:

Automated Product Counting & Classification

- Tracks every item on conveyor belts,

- Classifies products as good or defective,

- Detects production stoppages within seconds and sends alerts.

Automated Product Counting & Classification takes over repetitive tasks that drain human attention and significantly reduces the risk of overlooking defective units.

Visual Machine Cycle Monitoring

- Analyzes machine cycles through visual cues,

- Identifies micro-downtime invisible in manual reporting,

- Helps reveal inefficiencies that impact throughput.

This is especially valuable for predictive maintenance strategies, where downtime patterns can indicate components that need servicing.

Workforce Presence & Safety Analysis

- Ensures that critical stations are staffed,

- Uses silhouette recognition instead of faces for privacy,

- Supports safety measures around hazardous equipment.

Together, these solutions turn cameras into powerful industrial sensors capable of delivering real-time insights without intrusive hardware installations.

When Should Companies Invest in Computer Vision?

There are three clearly defined scenarios where adopting computer vision provides fast and measurable returns.

1. When Work Is Repetitive and Accuracy Declines Over Time

Human concentration naturally drops during monotonous tasks like inspecting parts or visually monitoring conveyor belts. Errors accumulate, quality fluctuates, and defect detection becomes inconsistent.

A computer vision system never gets tired — it maintains perfect consistency 24/7.

2. When the Cost of Errors Is High

A defective batch sent to customers can cause:

- returns and logistic expenses,

- contractual penalties,

- loss of trust and damaged reputation.

Defect detection powered by artificial intelligence spots issues earlier and more accurately than any human operator, preventing costly failures.

3. When Machines Are Mechanically Sound but Lack Digital Outputs

Many factories operate equipment built decades ago.

These machines are reliable, but “digitally silent.”

Instead of replacing them, integrating computer vision allows companies to:

- visually monitor machine states,

- track cycles,

- detect anomalies,

- estimate productivity,

- support predictive maintenance decisions.

It’s the most efficient form of retrofitting, giving old machines new life at a fraction of the cost.

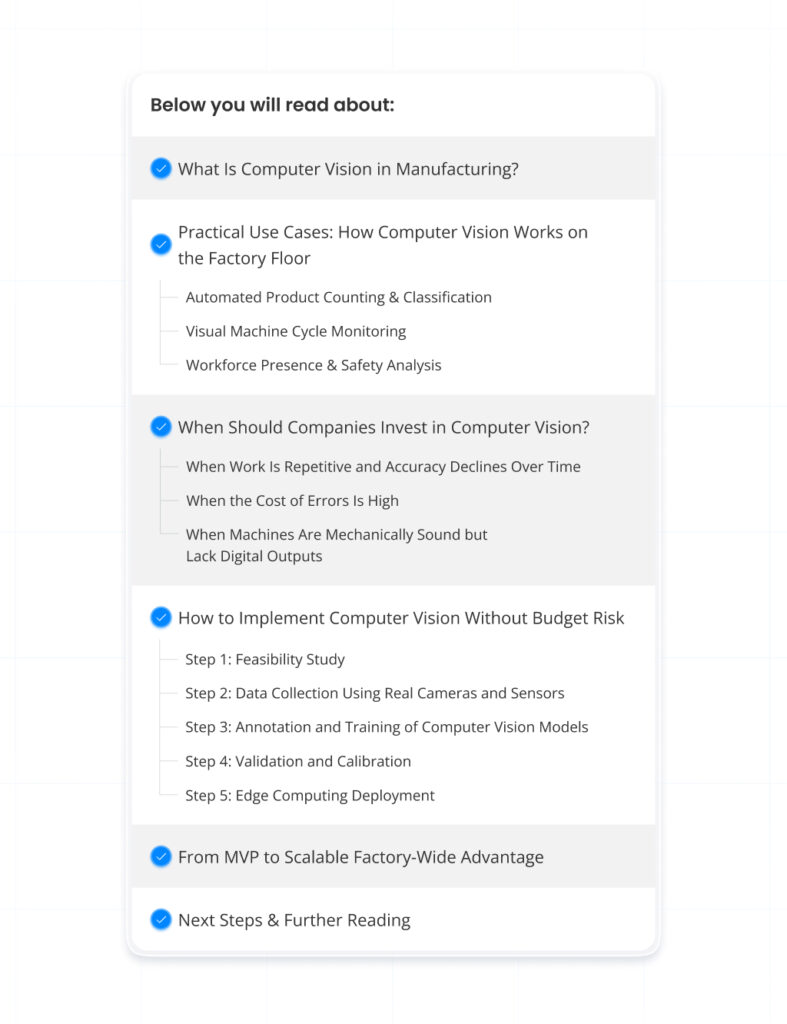

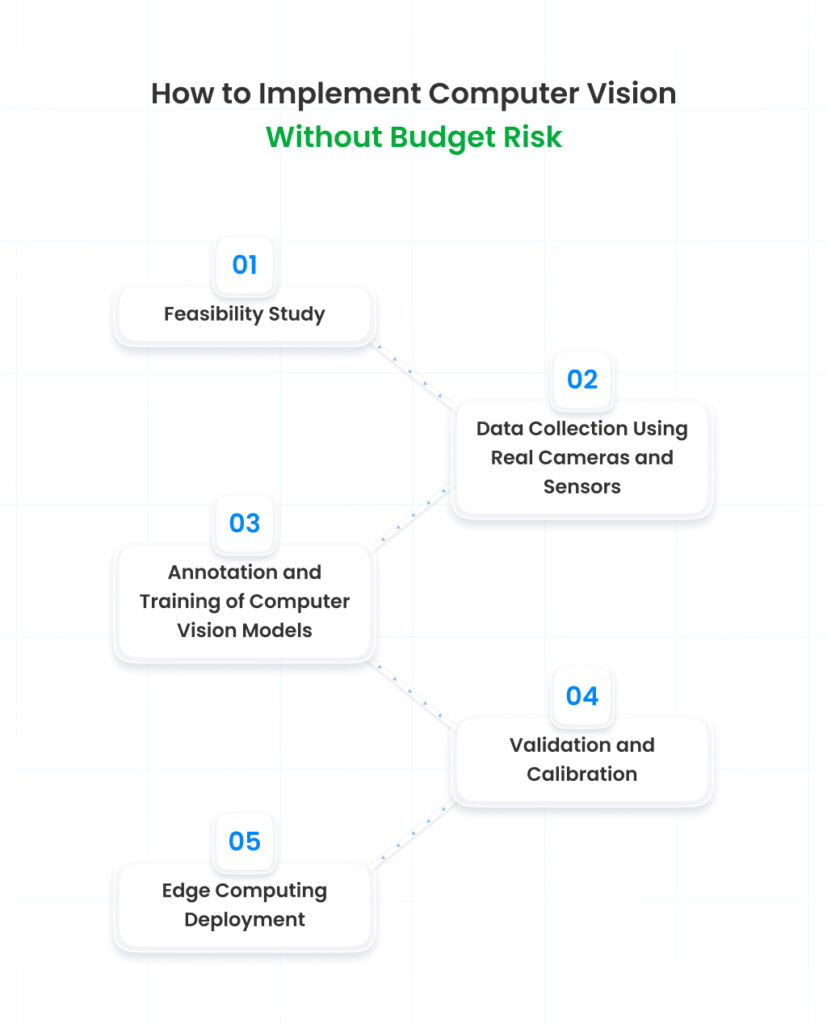

How to Implement Computer Vision Without Budget Risk

To avoid “black hole projects,” the implementation process must be predictable and transparent.

A proven Computer Vision in Manufacturing deployment follows these steps:

Step 1: Feasibility Study

Define a clear business objective — for example:

“detect defects on product X,” or “count items with 99% accuracy.”

Step 2: Data Collection Using Real Cameras and Sensors

Install high-resolution cameras directly on the production line. Gather data under real-world conditions: varying light, vibration, dust, and shifts.

Step 3: Annotation and Training of Computer Vision Models

Experts label data; models learn patterns specific to your factory.

This ensures reliable performance across production processes.

Step 4: Validation and Calibration

Models are tested on your actual line to ensure stability and accuracy.

Step 5: Edge Computing Deployment

Small on-site devices process frames locally — no cloud dependency, lower latency, stronger data protection.

This predictable path minimizes implementation risks and ensures fast time-to-value.

From MVP to Scalable Factory-Wide Advantage

Adopting computer vision does not require transforming the entire factory at once.

The safest and most cost-effective strategy is:

- Start with a single bottleneck or defect detection problem,

- Build a small MVP system,

- Measure improvements in efficiency, downtime, and quality,

- Scale the solution across additional machines or lines.

Companies that begin with one computer vision station often expand to full production networks over time, building a mature digital ecosystem step by step.

Learn more about the fundamentals of Computer Vision in this NVIDIA overview.

Next Steps & Further Reading

If you want to explore how Computer Vision in Manufacturing can optimize your factory, enhance defect detection, reinforce quality standards, or support predictive maintenance, Stermedia delivers practical, safe, and scalable solutions tailored to your production reality.

Reach out to our AI specialists to find the ideal MVP starting point.

Continue your exploration with related case studies:

1. Improving Production Lanes of An Automotive Giant

AI streamlined how one of the world’s largest car manufacturers reports and manages technical issues on production lines. The system automates problem analysis, speeds up response times, and improves process continuity. Result: fewer downtimes and faster decision-making.

2. Car Production Improved with Artificial Intelligence Predictions

A machine learning model predicts material consumption in a major car factory, eliminating waste and inaccurate orders. By analyzing production data, the company optimizes planning and minimizes losses. A practical boost to resource efficiency.

3. From Vision to Validation: Wakeb’s AI & Image Recognition Journey

This project shows how an initial idea evolved into a validated AI solution powered by image recognition. Stermedia supported concept refinement, model development, and MVP validation. A perfect example for companies starting small but aiming for reliable AI adoption.