Executive Summary

This case study explores the development of an AI-driven Energy Management System designed to optimise the performance of industrial compressor installations.

The initiative aimed to optimize energy losses, prevent unplanned downtime, and extend equipment lifetime through advanced data analytics and artificial intelligence.

By integrating domain expertise with AI software development, the team built and validated an intelligent model capable of predicting anomalies in compressor performance before they caused disruptions.

Challenge: The Need for AI-Driven Energy Management in Industrial Systems

Compressor systems are essential for industrial operations, but they are also among the largest consumers of electricity. For this client, the primary issue was clear and urgent: high energy costs caused by suboptimal load balancing and system inefficiencies.

The system was kept fully operational even during periods of very low or nearly zero demand, leading to unnecessarily high electricity bills and avoidable wear on equipment. The client wanted to eliminate these energy losses by ensuring that the compressed-air system operated intelligently — adjusting output to real demand and avoiding waste.

Two additional challenges also affected overall performance, though they were not the main drivers of the project:

- Frequent unplanned stoppages resulting from component wear and process variability — a natural consequence of running machines more than necessary.

- Limited visibility into real-time compressor behaviour and operational dependencies, which made diagnosing inefficiencies and planning improvements difficult.

Despite these secondary issues, the central pain point remained unchanged: energy costs were too high, and the organisation needed a data-driven, intelligent solution to finally regain control over its energy consumption.

For a broader industry perspective on AI-supported energy optimisation, see practical insights into AI-driven energy management

Approach: Building the Foundation for AI-Based Predictive Maintenance

The project followed a systematic methodology integrating industrial knowledge, data science, and software engineering.

1. Data Collection and Quality Assurance

Comprehensive datasets were gathered from pressure sensors, flow meters, and energy counters across multiple compressor units.

Data cleaning, synchronisation, and validation were conducted to eliminate missing values and ensure consistency.

This foundational work enabled reliable AI model training and improved overall data integrity.

2. Feature Engineering for Maintenance Prediction

Subject-matter experts collaborated with data scientists to derive features that captured machine dynamics — including air flow patterns, pressure stability, temperature variation, and demand cycles.

These engineered features became the backbone for predictive analytics in maintenance, enabling accurate detection of abnormal system behaviour.

3. Model Development and Evaluation

Machine learning models — such as regression, anomaly detection, and time-series forecasting — were tested and benchmarked.

The chosen model successfully correlated sensor fluctuations with energy consumption patterns and early signs of component degradation. Its predictions allowed engineers to act pre-emptively, reducing unnecessary energy consumption and scheduling maintenance based on real operational demand.

4. Integration and Validation

A dedicated data acquisition environment was deployed to enable continuous collection and processing of compressor telemetry. This infrastructure ensured that all operational parameters – including pressure, flow, temperature, and energy consumption – were consistently captured and stored for analysis. By centralising and structuring the data, the system created a reliable foundation for ongoing optimisation of power consumption.

The AI models were validated using both historical and live datasets, confirming stable forecasting accuracy and practical relevance for engineering teams. This validation demonstrated that the system could be trusted to support real-time decision-making and long-term improvements in compressor energy efficiency.

Solution: AI-Driven Energy Management System for Compressor Optimisation

The final solution represented an AI-driven Energy Management System built on continuous data analysis. While the system also contributed to better maintenance planning, its core purpose was to reduce unnecessary energy consumption through intelligent control and forecasting.

Key components included:

- Predictive models monitoring compressor health and forecasting energy consumption, enabling the system to proactively adjust operation and minimise waste.

- Data pipelines enabling real-time analytics from industrial sensors.

- Scalable architecture allowing cloud and edge deployment for various industrial environments.

Rather than replacing human expertise, the AI system augmented it — offering data-backed insights that empowered engineers to make faster and more accurate decisions.

This collaboration between human intelligence and artificial intelligence established a foundation for long-term digital transformation.

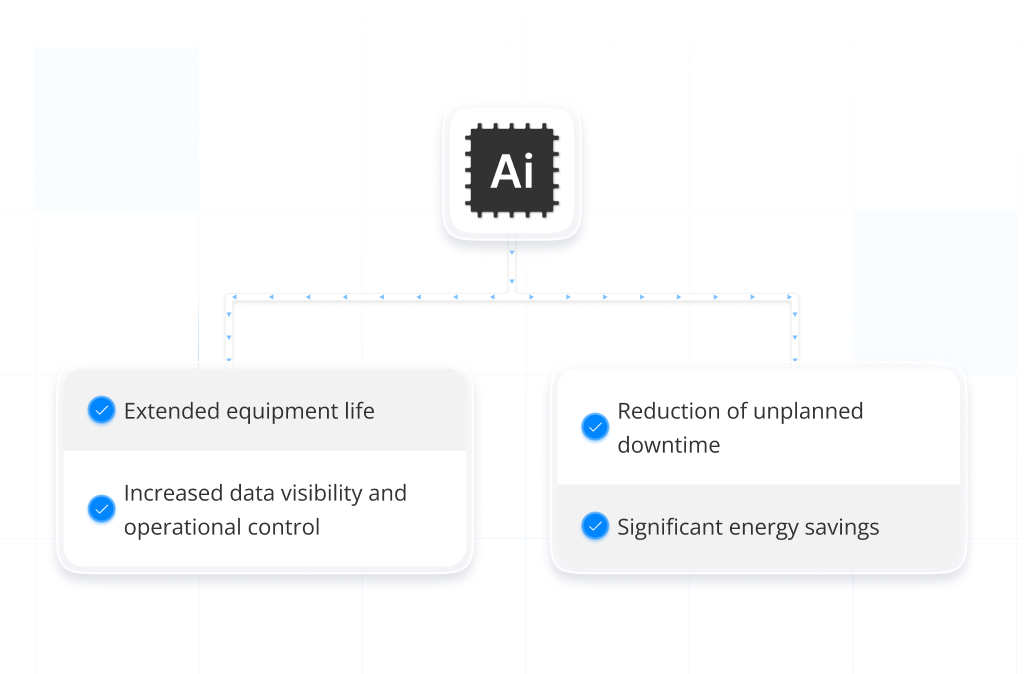

Key Results: Business Impact of AI-Driven Energy Management

The project produced measurable outcomes across operational and strategic levels:

- Energy Efficiency Improvements

AI-guided optimisation of compressor sequencing led to measurable reductions in energy waste during low-load periods. As a side benefit, reduced operating time helped lower mechanical wear and maintenance needs, further improving overall system efficiency. - Data Visibility and Decision Support

Real-time monitoring and AI-generated insights enabled continuous performance tracking and process optimisation. - Extended Equipment Lifetime

By balancing operational stress and maintenance timing, the system helped extend the lifespan of key compressor components. Because compressors ran only when needed, operational stress decreased, naturally reducing wear and extending service life even further. - Foundation for Scalable Industrial AI

The architecture is adaptable to other assets and production environments, creating a platform for enterprise-wide Predictive Maintenance adoption. - Reduced Unplanned Downtime

Predictive alerts allowed maintenance teams to act before failures occurred, lowering disruption costs and improving reliability.

All results were verified through system validation and client acceptance testing, confirming both technical robustness and business relevance.

Lessons Learned: Implementing AI-Driven Energy Management in Practice

The implementation highlighted that the success of an AI-based energy management system depends on more than algorithms — it requires process alignment, data reliability, and organisational readiness to act on insights.

Key takeaways:

- Data quality drives predictive accuracy. Calibrated sensors and consistent data acquisition are essential.

- Interdisciplinary collaboration is critical. Data scientists and engineers must co-create solutions.

- Transparency builds trust. Operators adopt AI systems more readily when outputs are interpretable.

- Scalable architecture ensures sustainability. Modular designs allow future expansion beyond pilot projects.

Conclusion: From AI Pilot to AI-Driven Energy Management Transformation

This project demonstrated how an AI-Driven Energy Management System can transform industrial operations from reactive problem-solving to proactive optimisation.

By leveraging machine learning and data engineering, the client achieved better control, higher reliability, and measurable sustainability benefits.

The collaboration proved that predictive models are not just about maintenance — they are a cornerstone of operational intelligence.

Through this foundation, the company is now positioned to evolve toward self-optimising production systems and more advanced AI-driven decision frameworks.

Next Steps & Further Reading

Turn data into action with AI-powered Predictive Maintenance.

At Stermedia, we help industrial organisations harness AI and analytics to enhance efficiency and sustainability.

If you’re ready to explore how predictive intelligence can improve your processes, contact our AI experts today.

Continue your journey into applied artificial intelligence by exploring more success stories:

- AI Software Development: Platform Takeover & Optimization – enhancing scalability and performance through custom AI development.

- Streamlining Tender Processes with AI Solutions – automating complex business operations through data-driven intelligence.

- AI in Healthcare: Screening Revolutionized – how predictive analytics accelerate diagnostics and clinical workflows.

For more expert insights, visit the Stermedia AI Blog and discover how AI is redefining innovation across industries.